Online Interactive Workshop

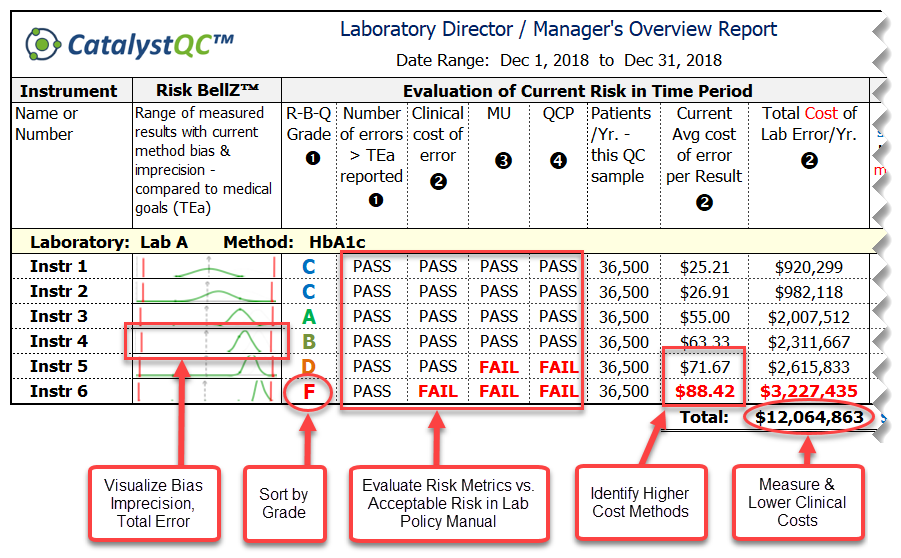

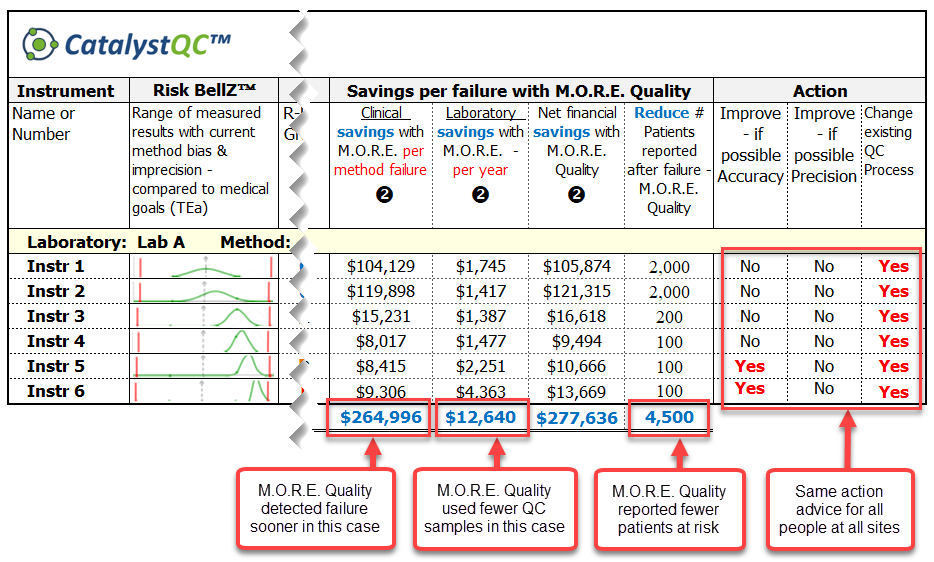

Use NEXT GENERATION technology in medical laboratory quality/risk management to project clinical savings throughout the health care system - a test case to study HbA1c.

Premiere

Special!

What are the clinical costs and risks to patients and healthcare systems of errors in HbA1c results that mislead doctors to either:

[A] mis-classify patient as low risk instead of high risk of diabetes, or

[B] think that patients are improving or not improving when the opposite is actually true?

Validate the effectiveness of existing quality control processes to detect medically-significant error. Prepare to be shocked by this realtime demo!

Regular Multi-Lab Workshop Price $497.00 Introductory sale $124.25

Use NEXT GENERATION technology in medical laboratory quality/risk management to project clinical savings throughout the health care system - a test case to study HbA1c.

Sign up now for the chance to submit your data!